Didn’t find what you’re looking for? Let us know your needs, and we’ll tailor a solution just for you.

End-to-End Supply Chain Management Solution

- Demand Forecast

- Forecast Accuracy

- Volume Forecast

- New Product Planning

- Collaborative Demand Planning

REPLAN – A complete Supply Chain Management Solution

REPLAN is a powerful supply chain management solution designed to strengthen every stage of your supply chain management process—from demand planning to inventory optimization.

By leveraging advanced analytics and real-time data, REPLAN enhances the accuracy of your demand forecasts, helping you make smarter decisions across all key supply chain management steps.

Cut operational costs, reduce excess inventory, and improve customer satisfaction—while maintaining agility and control throughout your entire supply chain.

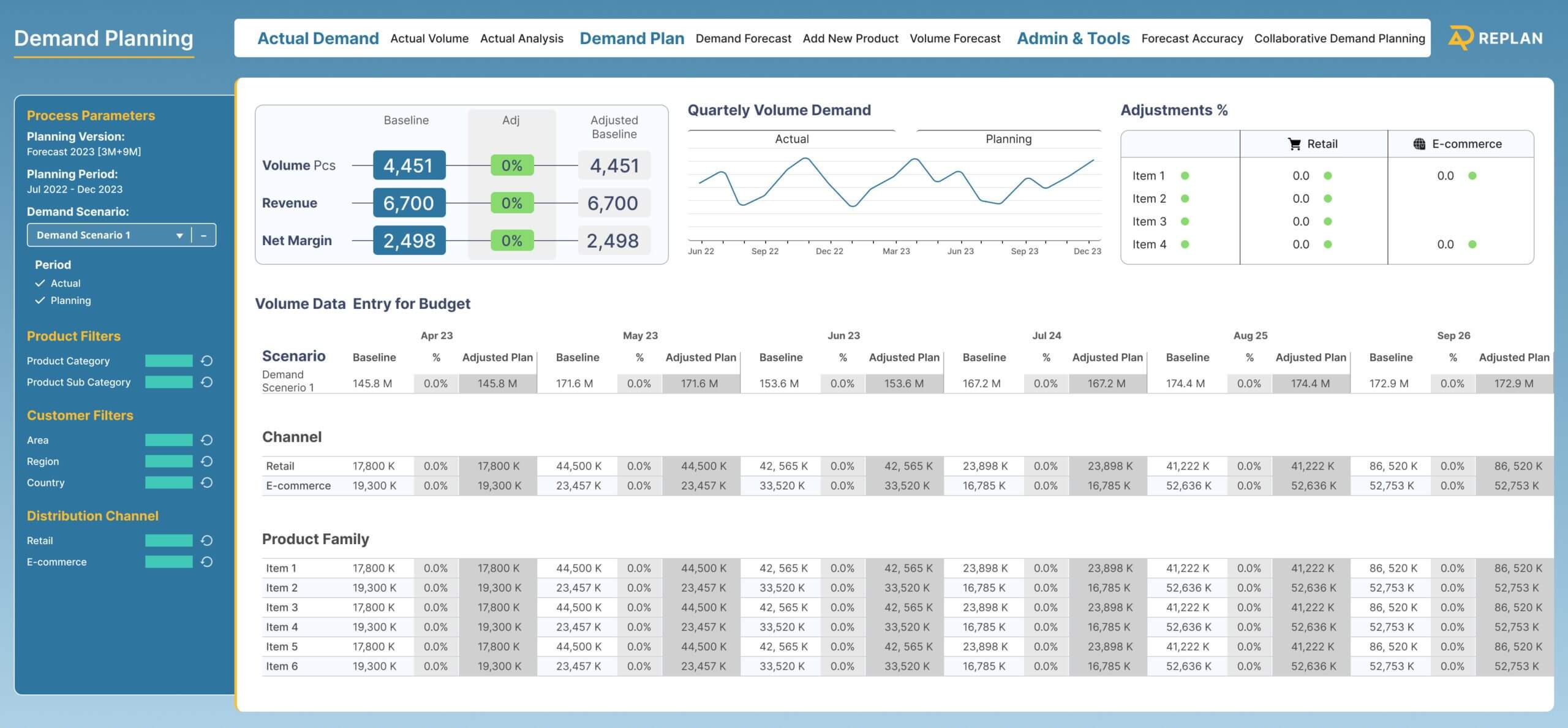

REPLAN - A Complete Demand And Supply Chain Planning Solutions

Demand Forecasting

Baseline forecasts are the foundation of demand planning. They act as a starting point for predicting future demand by leveraging historical sales data. A baseline forecast is a statistically generated prediction of future demand based solely on historical sales data. It’s essentially a projection of what demand would be if things continued exactly as they have in the past. This forecast removes the influence of factors like promotions, one-off events, or seasonality.

Forecast Accuracy Board

A forecast accuracy board translates often complex forecast metrics into a clear and easy-to-understand format. This allows everyone involved in demand planning, from senior management to department heads, to see how well forecasts are performing. It encourages continuous improvement in data collection, forecasting methods, and overall demand planning processes.

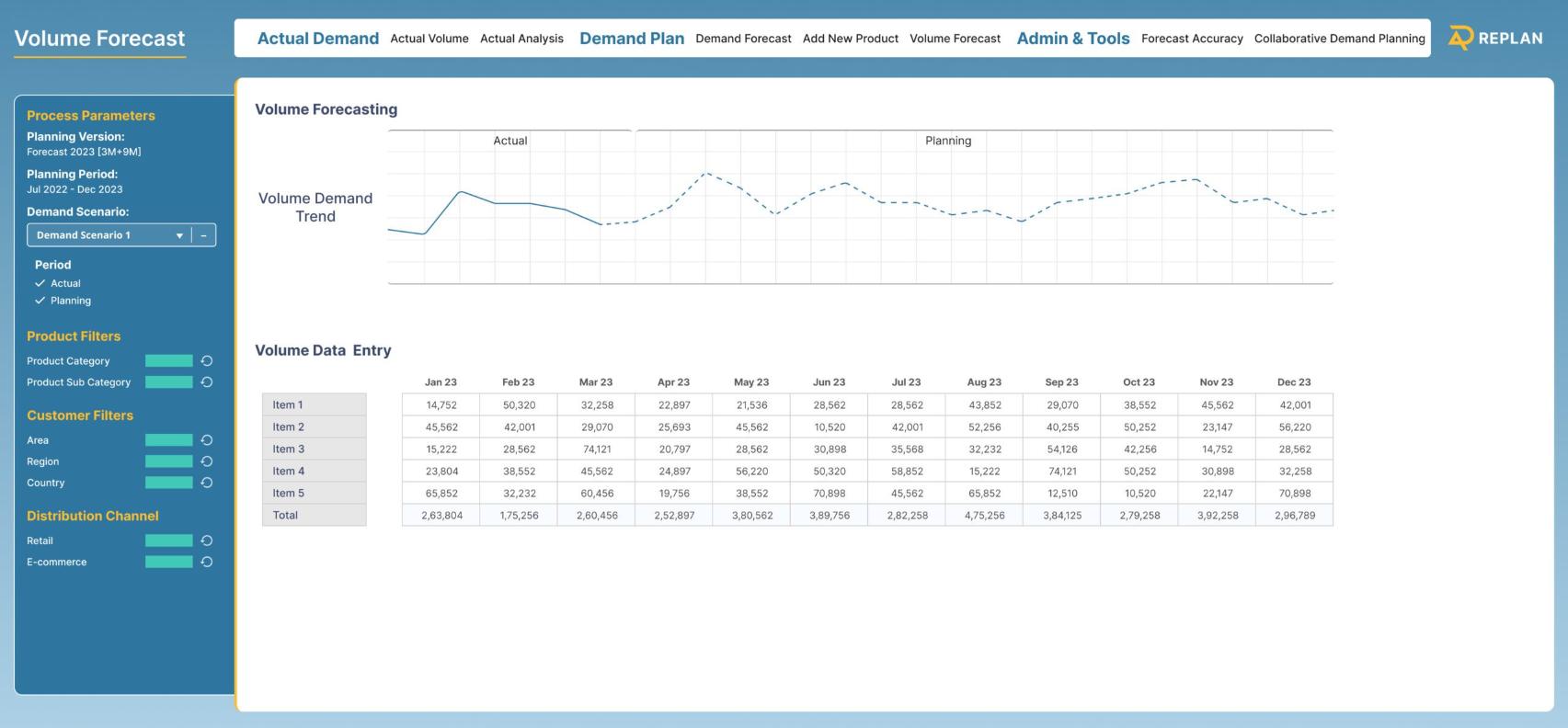

Volume Forecast

In demand planning, a volume forecast specifically refers to predicting the total quantity of units you expect to sell within a certain timeframe. It’s essentially a breakdown of the baseline forecast, focusing on the number of items rather than just the overall sales value. It is based on understanding the demand patterns, resource allocation, product life cycle, market research and other relevant basis of calculations.

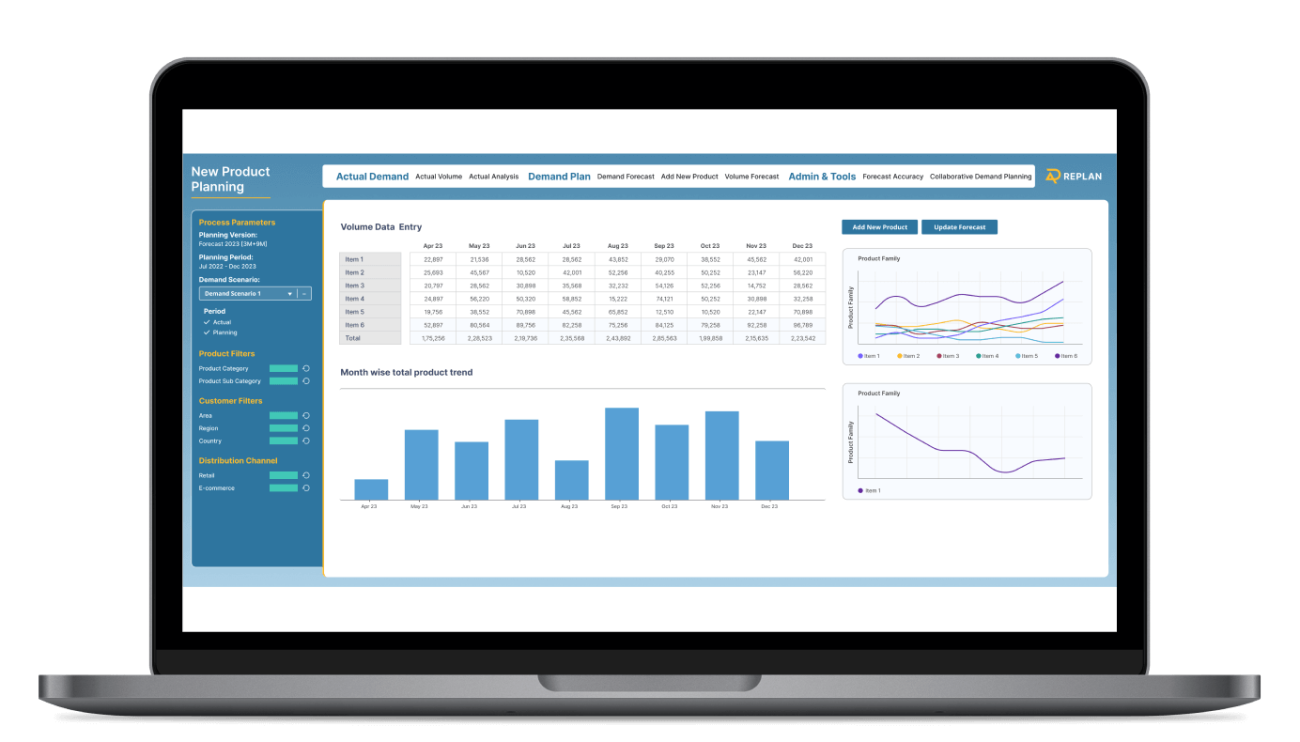

New Product Planning

New product planning presents a unique challenge in demand planning because there’s limited historical sales data to rely on. It is based on understanding the demand patterns, market analysis, early testing and feedback, scenario planning and other statistical methods to determine demand.

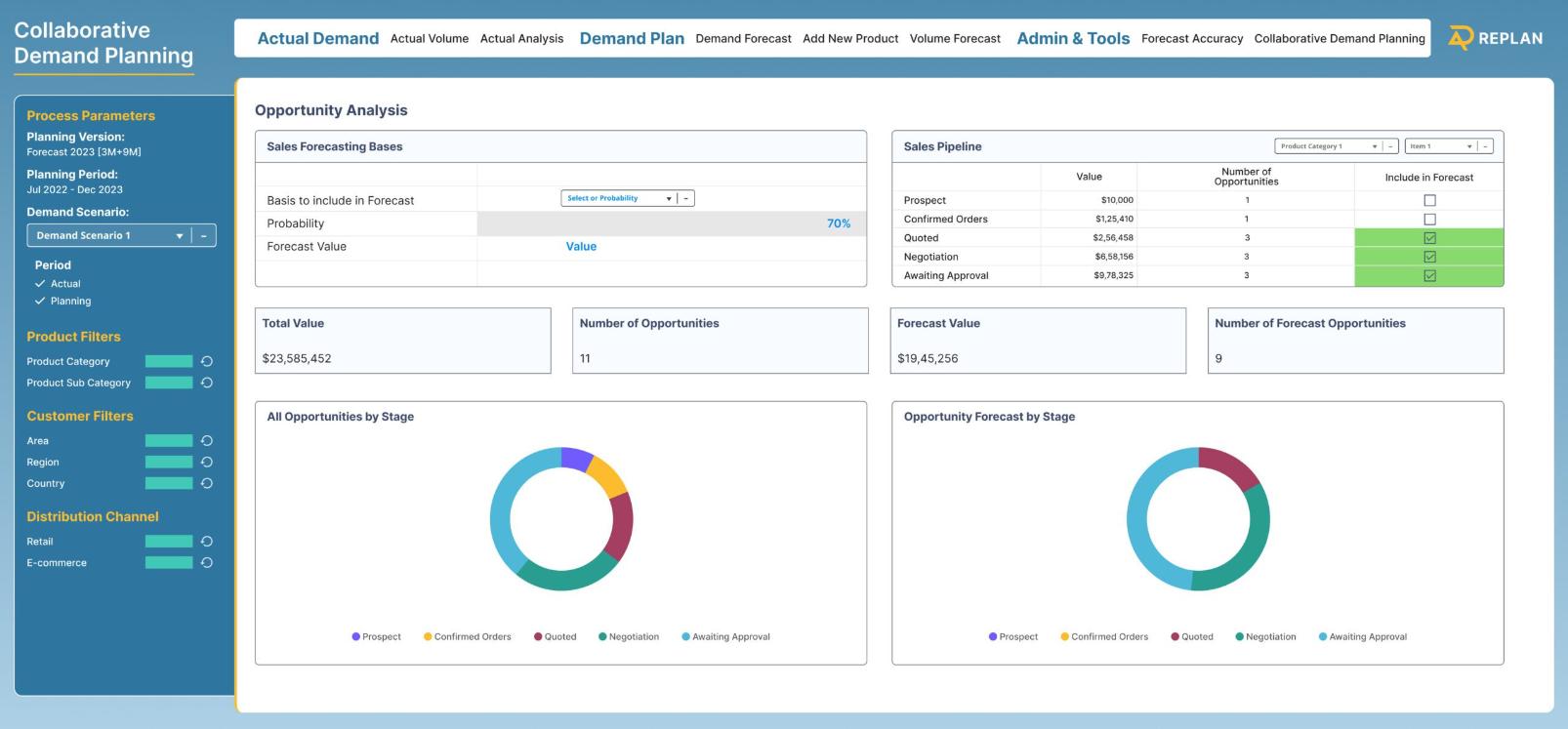

Collaborative Demand Planning

Collaborative demand planning takes traditional demand planning a step further by involving multiple stakeholders in the forecasting process. Each stakeholder contributes their unique perspective and information relevant to demand forecasting. Through regular communication and collaboration, all parties work towards a single, agreed-upon forecast that reflects a holistic view of the market and internal factors.

Salient Features of Supply Chain Management Solution

Historical Data Analysis

Leverages past sales data to identify trends, seasonality, and customer buying patterns. This historical foundation empowers better forecasting for future periods.

Market Research Integration

A key Purpose of Supply Chain Planning is to incorporate external market data such as competitor analysis, industry trends, and economic forecasts to gain a holistic understanding of demand drivers and align supply strategies accordingly.

Scenario Planning

Enables the creation of multiple forecasts based on different market conditions, allowing businesses to prepare for various eventualities and adapt strategies accordingly.

Statistical Forecasting Techniques

Utilizes statistical methods such as exponential smoothing and regression analysis to create quantitative forecasts, enhancing accuracy and aligning with demand planning best practices.

Collaboration and Communication

Fosters seamless communication between sales, marketing, and finance teams, ensuring everyone is aligned on demand expectations and inventory planning.

Continuous Improvement

Provides tools to monitor forecast accuracy and identify areas for improvement. This iterative process ensures demand plans stay relevant and responsive to market dynamics.

Key Benefits of Replan

The current business landscape is full of complexities and obstacles that hinder growth. Therefore it’s crucial to address these challenges head-on to ensure business success.

- Better inventory planning

- Improved customer satisfaction

- Improved supply chain efficiencies

- Data driven decision making

- Real time analysis

Blog & News Update

How Supply Chain Forecasting Can Transform Your Business

Imagine running your business with a clear view of the future, knowing exactly what customers will want, when to restock,

November 5, 2025

Complete Guide to Supply Chain Scenario Planning

Running a business is never easy, especially when you depend on many different parts working together. One small problem—like a

October 9, 2025

Demand Sensing vs Demand Forecasting Made Simple

Predicting what customers will want—and when—is one of the biggest challenges for any business. Whether you’re managing a retail store,

October 8, 2025

Demand & Supply Chain Planning Solutions to Optimize Operations & Boosting Profits

Stop relying on outdated methods for demand & Supply Chain Management Solution? Our cutting-edge demand planning & forecasting solution leverages smart and efficient methods to give your business a competitive edge in today’s fast-paced marketplace.

Our platform enables you to create precise forecasts tailored to your needs, it utilizes advanced Methods of Demand Forecasting to make informed inventory decisions, and adapt swiftly to market changes.

Don’t let uncertainty hold your business back – try REPLAN for demand & supply planning today and start making confident, data-driven choices that drive growth and profitability.